Flex-N-Gate succeeds at automotive sub-assembly using Apera AI’s 4D Vision

Flex-N-Gate turned to Apera AI’s 4D Vision technology to resolve automotive clip placement

Flex-N-Gate was experiencing issues with a “blind” robot’s ability to place automotive clips for injection molded interior subassemblies. The robot was missing the clip towers and causing quality issues and part breakage. By using Vue robotic vision software, the issues were resolved and part acceptance climbed above 99%.

Application description and performance highlights

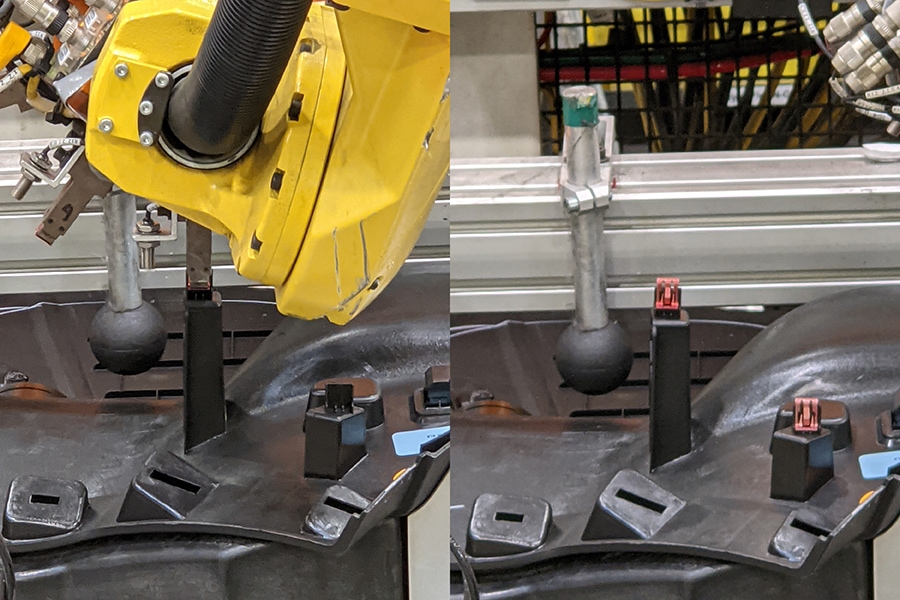

- Flex-N-Gate is using a Fanuc industrial robot to install small clips into an interior subassembly. Injection molded parts are subject to dimensional variation, so the robot is missing the clip tower locations.

- They are experiencing an 88-90% success rate in placement when operating a blind robot. Some of the parts have to be discarded because of breakage.

- The engineering team and plant management decide to add vision to the robot’s capabilities and choose Apera AI’s 4D Vision technology.

- After installing the Apera AI 4D Vision technology, clip placement and quality acceptance rates are both over 99%.