Advanced Robotic Sorting With Apera Vue Software

Distinguishing the indistinguishable, Apera AI's Vue software is revolutionizing the robotic sorting landscape, ensuring even the minutest differences between objects don't go unnoticed.

Distinguishing the indistinguishable, Apera AI's Vue software is revolutionizing the robotic sorting landscape, ensuring even the minutest differences between objects don't go unnoticed.

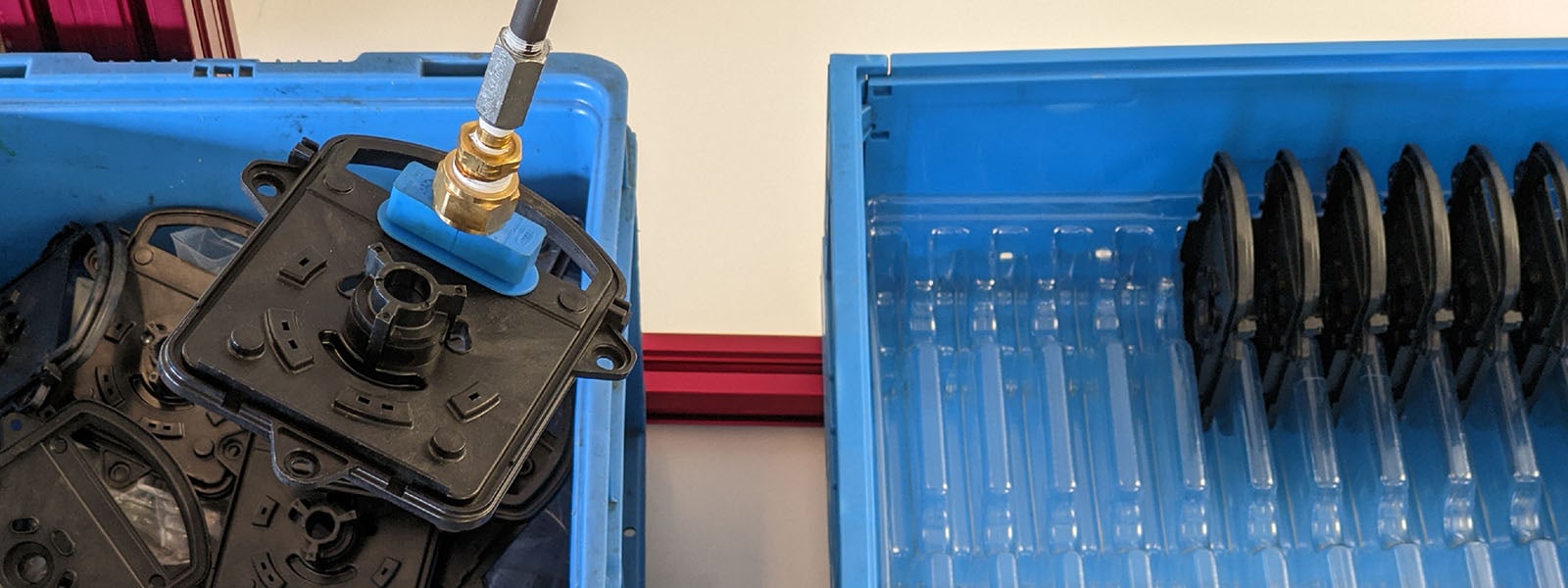

From translucent medical device parts to black injection-molded plastic components with minute variations, industries are turning to Vue software for its unparalleled sorting capabilities. Our software has proven its mettle in scenarios where even human eyes falter.

Apera AI’s Vue robotic vision software allows a robot to

Vue software boasts an industry-leading vision cycle time, ensuring rapid and precise sorting. Even when objects have subtle differences or challenging finishes, Vue’s AI-powered vision is up to the task.

The best part? Since we take care of creating the vision program, you don’t need to be a vision expert to create a vision-guided robotic assembly cell.

Setting up Vue for sorting is a breeze. We train our AI to completely understand your parts and return a ready vision program to you. You won’t have to set up structured lights or lasers to achieve a working cell, since Apera systems do not need them

We use CAD models or 3D scans to train our AI, and factor in things like texture, markings and finishes to make sure the sorting process is accurate and consistent.

Feedback from manufacturers is that our vision system saves them money, and makes their operations more flexible.

When an operator can be used for another job, there’s a labor savings. But our vision software unlocks higher ROI.

With Vue, you do not need fixtures or additional automation to stage raw parts. You can dump different parts into bins and the robot can sort them out. Once sorted, the vision system can guide the part on to the next step, whether that’s into a CNC, or to a conveyor, or being assembled with another part.

Apera AI’s vision software for sorting is robot agnostic. You can choose the best robot or cobot for the job, right down to the best gripper.

We support major brands such as ABB, FANUC, Denso, Universal Robots, Yaskawa, Doosan, Epson, KUKA, Kawasaki Robotics, Mitsubishi Electric, Omron and Stäubli, with more coming soon.

Our AI-driven vision system mimics human perception, offering fast and reliable object recognition coupled with precise robotic path planning. Curious about the mechanics behind it? Dive deeper by clicking the link.