4D Vision applications

Apera AI's Vue robotic vision software makes robots smarter and faster. Applications like bin picking, packaging, kitting, assembly, sorting, machine tending and de-palletizing can be made better with 4D Vision technology.

Apera AI's Vue robotic vision software makes robots smarter and faster. Applications like bin picking, packaging, kitting, assembly, sorting, machine tending and de-palletizing can be made better with 4D Vision technology.

Fast, reliable random bin picking is the holy grail of automation. If you choose Apera AI for automated bin picking, you will have chosen wisely.

Under ambient light, an Apera AI system can handle difficult use cases like clear and shiny objects with an industry-leading vision cycle time as low as 0.3 seconds. That means you can hit the 2,000 picks per hour mark.

Our AI-powered vision software is taught to understand an object’s geometry, finishes, markings and more in order to quickly and precisely pick it from the bin. No custom programming needed.

Robotic guidance is the ability of robots to navigate and manipulate objects in their environment based on sensory input, primarily visual. This involves using cameras and sensors to guide the robot’s movements and actions, allowing it to perform precise and accurate tasks with Apera AI’s built-in collision avoidance.

By opting for Apera AI’s solutions, industries can benefit from robots that can handle tasks with human-like speed and intelligence. Whether it’s picking objects from a bin, assembling parts with sub-millimeter precision, or packaging multiple item shapes and finishes, Apera AI ensures that robots can perform these tasks efficiently and reliably. Their advanced vision system, combined with AI-driven algorithms, ensures that robots can thrive in high-mix, flexible manufacturing environments, handling different parts with minimal changeover times.

Put all of the pieces together by using Apera AI in your new assembly lines or workcells.

An industrial robot or cobot guided by Vue software can complete a multi-part assembly with speed and precision. And the workcell can be constructed with no specialized fixtures—parts can be taken from a random bin and put in place.

Vue can understand the geometry and markings on parts so they are correctly oriented when assembled. This is especially useful when parts are removed from nested packing configurations.

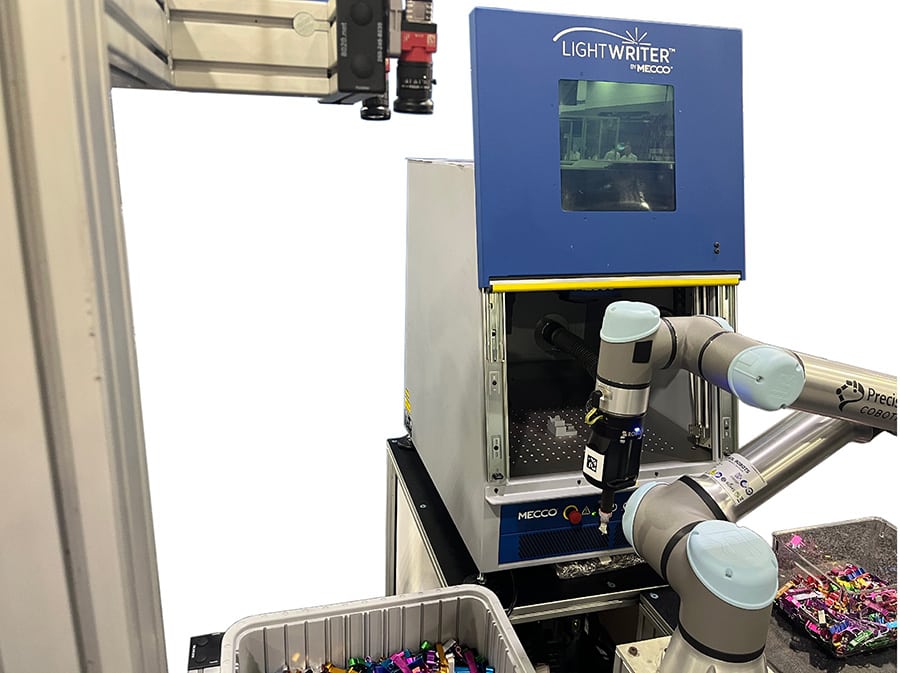

Automated machine tending is exploding in popularity as manufacturers look to use their labor force more efficiently. You can run leave machines operating autonomously, with a robot taking care of loading/unloading.

Choosing Apera AI for machine tending means being able to eliminate costly pre- and post-machining fixtures. Our Vue software be repeatably handle objects like shiny aluminum blocks out of a random bin into a CNC or laser marking machine. The robot can then handle the finished part on to another manufacturing step.

Robots powered by Vue software can thrive in high-mix, flexible manufacturing. You can run different parts with shorter changeover times.

Even when there are very small differences between objects, Vue software will be able to sort them out. Apera AI can help you make productivity gains in robotic sorting applications.

We have examples where even human eyes struggle to tell objects apart. Multiple customers who use our software to sort translucent or clear medical device parts. Another example is black injection-molded plastic parts where pins only a few millimeters long are the only difference, and they are picked and sorted from a black conveyor belt.

Vue software can help you improve productivity in packaging and kitting applications where speed, precision and label orientation really matters. Consumer packaged goods and pharmaceutical companies can run high-mix, flexible robotic workcells.

AI-powered vision can understand the position of labels and correctly orient them within a package, even when the objects are clear or shiny. Objects can be pulled repeatably from mixed or separate bins, or conveyors. This includes intelligence for when labels are hidden on the other side of the object within the bin, and must be turned around.