AI-powered vision for automotive manufacturing

Solve automotive manufacturing problems in robotic guidance, bin picking, assembly, and machine feeding using AI-powered vision software.

Solve automotive manufacturing problems in robotic guidance, bin picking, assembly, and machine feeding using AI-powered vision software.

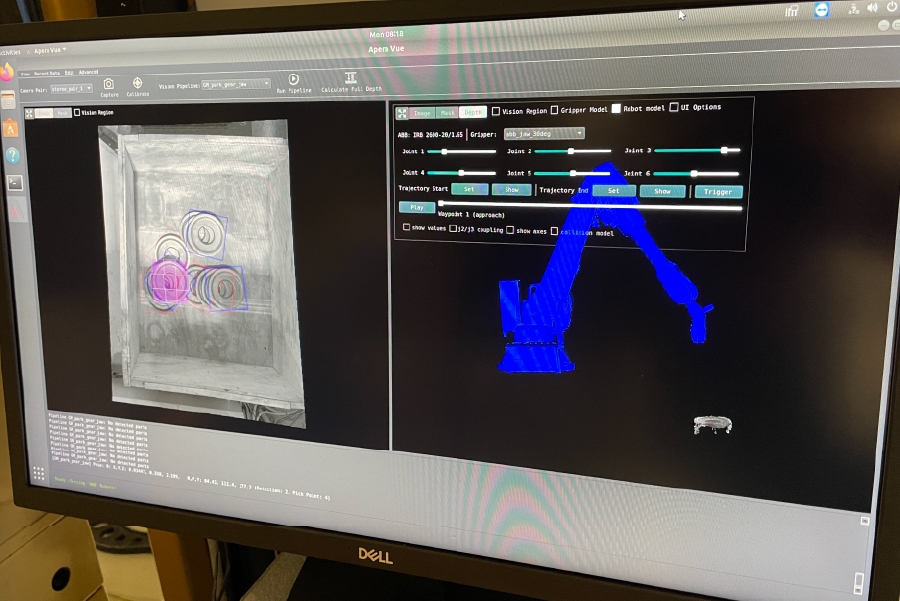

Apera AI makes vision software called Vue that guides robots as they perform a variety of manufacturing tasks. This includes bin picking, material handling, assembly, kitting and feeding machines.

We are trusted by the manufacturing teams of more than 10 leading automotive manufacturers and Tier 1 suppliers with combined revenue of more than $400 billion. Customers that have publicly shared their use of our products include Ford, Flex-N-Gate and Linamar Corporation.

If your automotive plant is racking and de-racking parts, eye-in-hand vision is for you. The robot-mounted cameras scan the area to find the racks and the next pickable hood. The robot can then handle the part with precision for the next step, whether that's assembly, welding or any other action.

Choosing vision-guided robotic material handling spares your people from hard, repetitive lifting. Repeatable racking and racking means they can focus on part quality and improving other areas of your plant.

Make real gains in productivity with an industry-leading total vision cycle time as low as 0.3 seconds. This is 10X faster than conventional vision systems.

Training this task into our AI involves more than 1 million simulated cycles. We train to the point where the task is 99.99% successful. This process happens in parallel to designing the cell—use of the robot cell is not needed—so the implementation process is shortened.

Badr Dowcet, Process Engineer, Hastech, a Linamar Corporation company.

See Linamar's Story

Apera AI's application engineering team performs a full assessment of your project. We agree on vision system performance goals with you. If we don't meet them, we refund your vision system purchase.

Don Cumming, General Manager, Flex-N-Gate

See Flex-N-Gate's story

If you have an underperforming vision-guided robot or a blind robot, Apera AI can help. Read our blog about retrofitting cells for better performance.