Vision retrofits are the quick automation wins you need to do now

Have a robotic cell that bugs you? The one that only works part of the time, when you’re not fixing its problems. It could be vision-equipped already or operating blind with fixtures. If any cell is failing in >10% of its operation, a vision retrofit is something you should consider.

What is a vision retrofit?

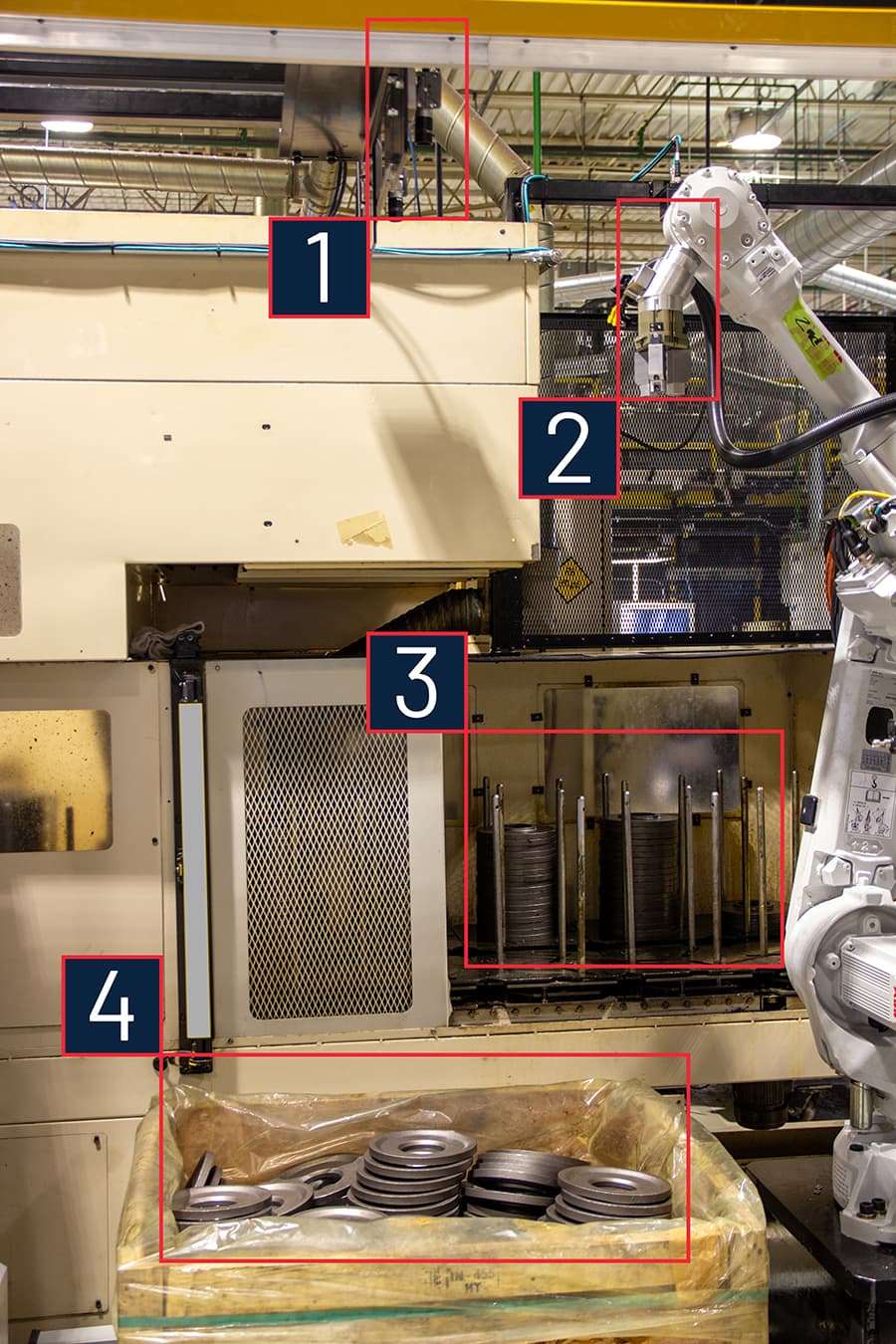

A vision retrofit is to install the latest AI-powered vision technologies to optimize the performance of a robotic cell. These technologies can significantly improve productivity by allowing robots to operate faster in a wider range of operating conditions and account for randomness intelligently. By upgrading existing 3D camera or fixtured setups with this AI-powered solution, companies can improve their operations and gain a competitive edge.

Four reasons you should do a vision retrofit now

You’re not reinventing the wheel, so it’s cost efficient.

Automation can be expensive when you’re designing from scratch. But in a retrofit, the robot’s already there. You already know what it needs to do and have a performance baseline to compare against.

With AI-powered vision you only need to add an extrusion above the cell for 2D cameras (or just remove the existing 3D camera). With a focused investment under $50K, a few hours of downtime and a project time under six weeks, you could have a cell performing faster and more reliably.

Operates in any light conditions with all object finishes.

If you have an existing vision system for robotic guidance, you probably know the pain of lighting and object finishes. When the sun comes through the window, or you need to pick shiny objects, the vision system stops working. AI-powered vision works by this rule—if a human can see it, an AI-driven vision system can, whether that’s in sunlight or nearly dark conditions.

AI-powered vision is just faster and smarter.

Using AI, a vision system can quickly process and analyze a lot of visual information in real-time. Robots can make decisions and adjust their actions very quickly. Training AI over about 1 million cycles makes for a reliable process before deployment, and this can happen in parallel to the cell continuing to operate.

AI-driven vision can achieve a total vision cycle time as low as 0.3 seconds—that’s 10x faster than a “fast” cycle using conventional 3D vision. The result is faster production, less downtime, and smoother workflows, which increase overall productivity. Improvements that were pushed aside because they couldn’t hit a target should be reconsidered.

Safer, happier workers

As robots become better at handling complicated tasks, human workers face fewer risks. Robots can take on repetitive and physically demanding jobs, reducing the chances of injuries and making the workplace safer. This also means workers can focus on more creative and supervisory roles, boosting their happiness and job satisfaction.

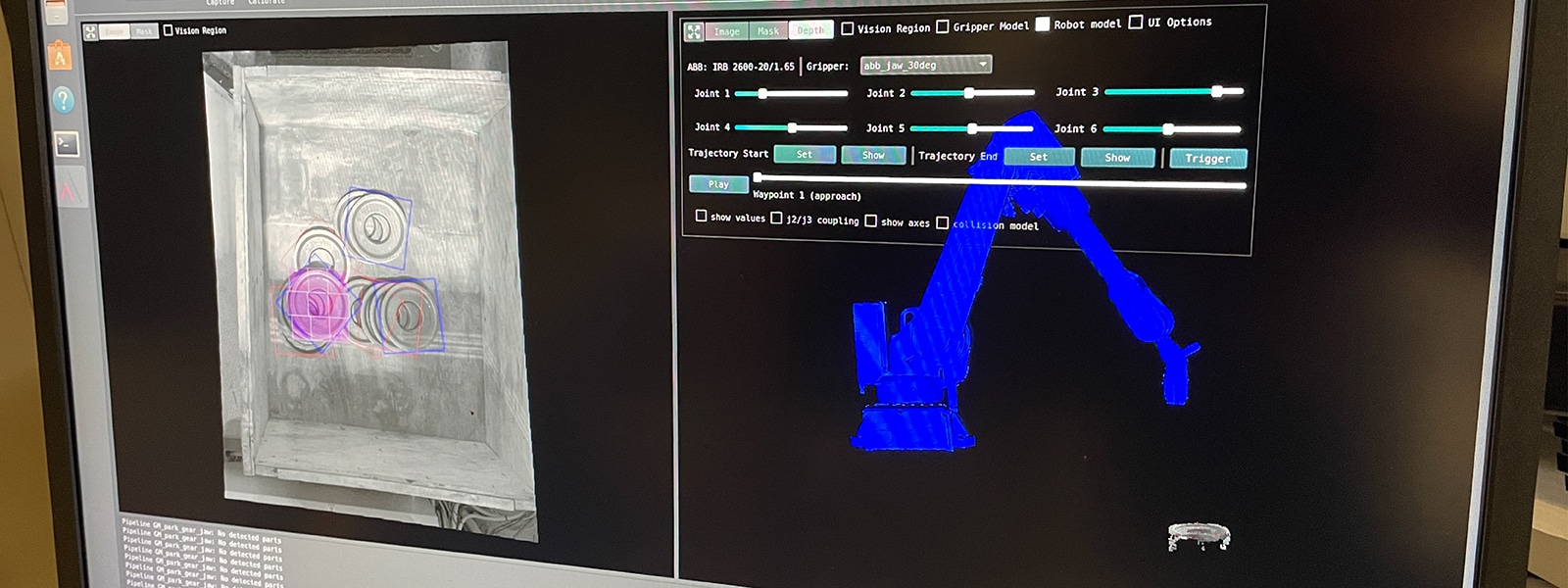

How does AI-powered vision work?

The quick version is that we train your robot’s task into our AI software technology. For example, a bin picking or machine tending task would be trained using your robot model, end of arm tool, objects being handled and the robot’s task. Usually, this takes around 1,000,000 simulated cycles. Apera AI provides a ready robotic program back to you—no vision programming necessary.

When the robotic program is ready, we’ll be at your site with one of our certified partners to support the vision system’s installation. The process is risk-free to you since our purchasing terms guarantee your satisfaction.

How do I take the next step?

Check out our page about Apera Vue robotic vision software to learn about what it can do. Our 4D Vision technology page describes how the technology works.

If you’re already convinced, fill out the form below and we’ll have an automation expert reach out to talk about your retrofit.