Machine Tending is a Robot's Job.

Do more with less by using Apera AI vision software to guide robots feeding CNC and laser marking machines.

Do more with less by using Apera AI vision software to guide robots feeding CNC and laser marking machines.

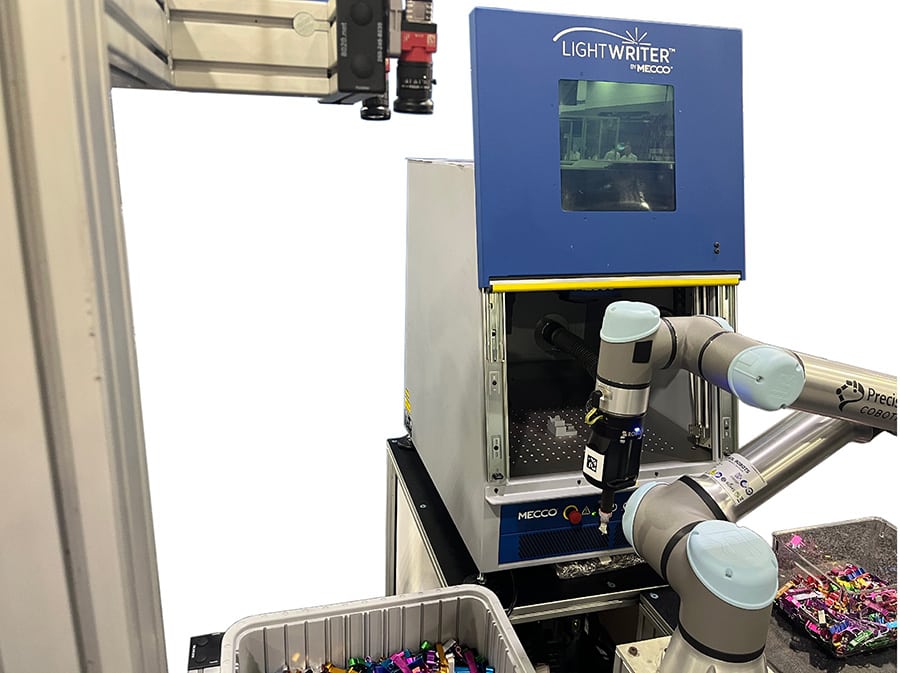

This is a Universal Robots cobot feeding a laser marking cell designed and sold by Precision Cobotics.

Using robots to feed and remove finished parts from CNC and laser marking machines allows manufacturers to re-task labor to less repetitive work, or operate extra shifts for part production.

Apera AI’s Vue robotic vision software allows a robot to

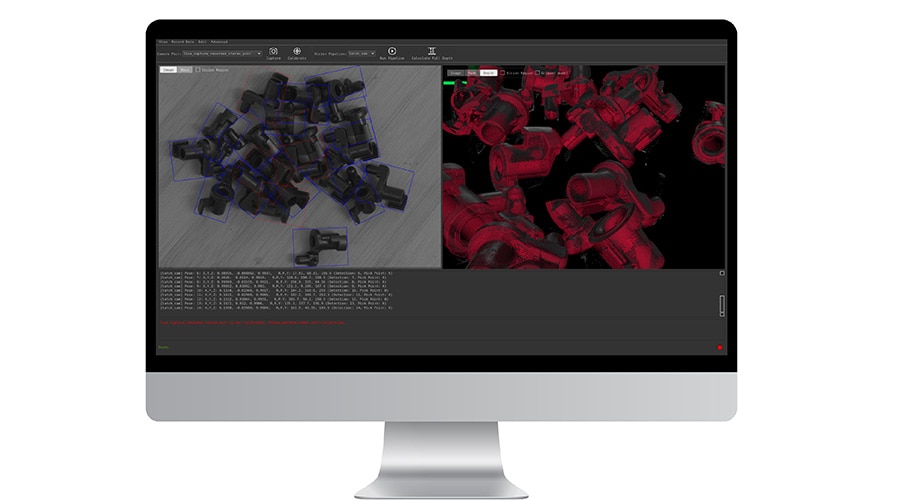

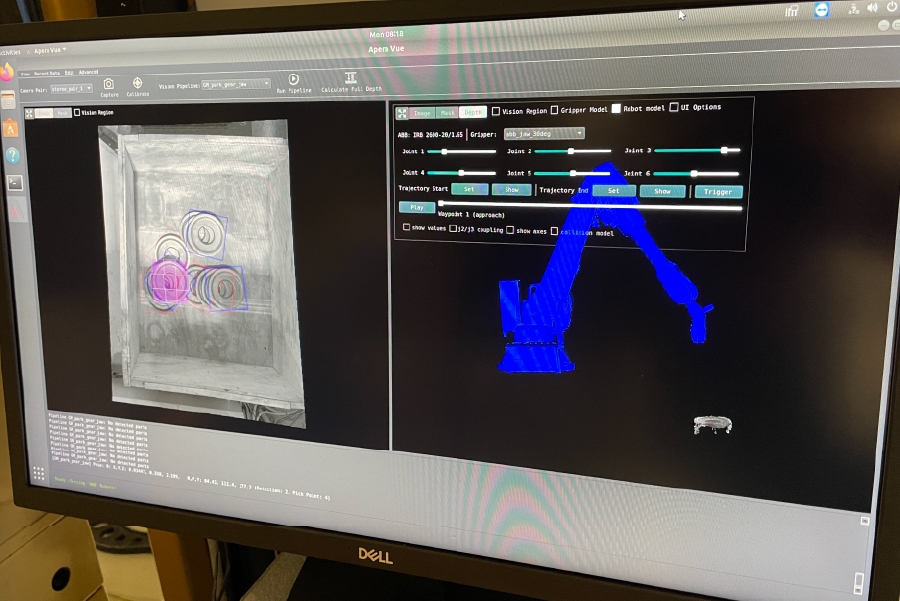

Vue’s AI processing helps the robot perform the role of a human operator. It performs the path planning, pose estimation and grasp intelligence to take a raw part and place it precisely in a machine. It can then remove the machined part and move it to the next manufacturing step.

Vue software requires less vision expertise and no custom programming. Multiple parts can flow through CNC and marking machines, with Vue fully understanding how to handle each part.

A Vue system operates under ambient light with no special cameras, lighting systems or sensors needed. Changes in lighting conditions will not affect the system’s operation.

Parts are taught into our AI system using CAD models or 3D scans. The object file is loaded into the Vue software. After simple calibration processes, the part is ready to handle into the machine.

Feedback from manufacturers is that our vision system saves them money, and makes their machine tending operations more flexible.

When an operator can be used for another job, there’s a labor savings. But our vision software unlocks higher ROI.

With Vue, you do not need fixtures or additional automation to stage raw parts. Our software can have the robot pick parts from bins, and when machining is done, place them into bins, on to conveyors, or into their final packaging.

The alternative is expensive fixtures and more human involvement, which can erase your ROI.

Apera AI’s vision software for machine tending is robot agnostic. You can choose the best robot or cobot for the job, right down to the best gripper.

We support major brands such as ABB, FANUC, Denso, Universal Robots, Yaskawa, Doosan, Epson, KUKA, Kawasaki Robotics, Mitsubishi Electric, Omron and Stäubli, with more coming soon.

Achieve 10X faster processing with an industry leading vision cycle time of just 0.3 seconds, boosting robot productivity and ensuring precise, error-resistant object handling.